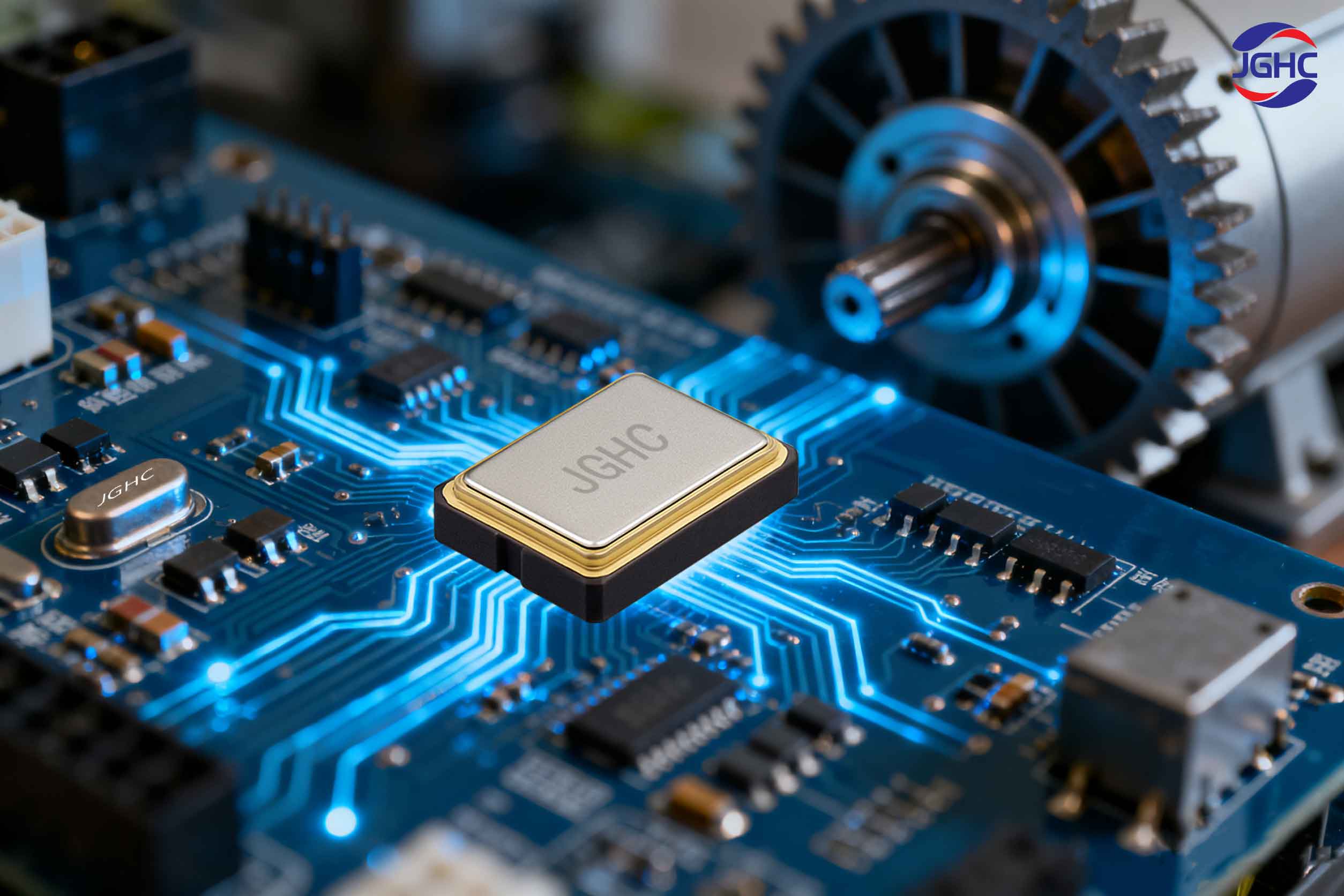

The Key Role of Crystal Oscillators in Motor Control The Invisible Core of Precision and Stability

In modern industry and intelligent manufacturing, motor performance has become the foundation of system reliability. Whether in electric vehicle drives, industrial robots, drones, or power tools, motor control systems rely on precise clock sources — and at their heart lies the crystal oscillator, a key component ensuring timing accuracy and stability.

1.The Role of Crystal Oscillators in Motor Systems

Motor control systems require precise timing signals to drive power devices, sample sensor data, and perform closed-loop control. Crystal oscillators provide high-stability and high-precision clock signals, ensuring that MCUs or driver ICs operate under accurate timing references:

- Accurate speed control: Maintain precise motor speed through a stable frequency reference.

- Position and feedback synchronization: Ensure real-time alignment between encoder signals and control logic.

- Stable PWM output: Reduce vibration and noise, improving system response speed.

-

Communication timing reference: Provide accurate timing for CAN, LIN, and UART interfaces to prevent control delays.

2.Typical Application Scenarios

- EV Motor Control Systems

High-stability active oscillators (25–50 MHz) provide precise reference frequencies for motor control chips, ensuring torque stability and rapid response. - Industrial Servo Motors and Robotic Drives

Temperature-compensated (TCXO) or voltage-controlled (VCXO) oscillators enable precise synchronization for multi-axis consistency. - BLDC and Home Appliance Control Boards

Low-frequency passive oscillators (8–16 MHz) are used in MCU clock circuits, balancing cost and performance. - Drone Electronic Speed Controllers (ESCs)

Differential oscillators (25–100 MHz) support high-speed PWM and data communication for precise flight control.

3. JGHC Crystal Oscillator Solutions for Motor Applications

| Type | Frequency Range | Features | Typical Application |

| Passive Crystal | 8~40MHz | High stability, compact size | MCU clock, PWM control |

| Active Oscillator | 1~170MHz | Strong drive, anti-interference | Motor control IC |

| TCXO | 10~52MHz | Temperature compensated, high accuracy | Servo control, robotics |

| VCXO | 10~200MHz | Adjustable frequency output | Synchronization, variable frequency systems |

4. Conclusion

In the era of intelligent drive, a high-quality crystal oscillator is the invisible guarantee of motor stability.

JGHC continues to provide global customers with high-precision, low-jitter, wide-temperature clock solutions, enabling motor control systems to achieve superior performance and reliability.

Prev: Maintenance and Servicing of AGISEAL Electrosurgical Generator SL100M

Next: Lab-Quality Thrombosis Testing with Poclight D-Dimer POC CLIA